Elevators have become an essential form of transportation in modern buildings, providing a quick and easy way to move between floors. The hydraulic systems of elevators are responsible for ensuring that they function smoothly and efficiently. However, without proper maintenance and upkeep, these systems can fail, causing serious harm to both the people using them and the building itself. One critical component of elevator hydraulic systems is hydraulic elevator oil.

Pain Points of Hydraulic Elevator Oil

Hydraulic elevator oil is a critical component of an elevator's hydraulic system. Unfortunately, many building owners and property managers don't understand its significance and are unaware of the risks associated with neglecting their elevator's hydraulic oil.

Some common pain points associated with hydraulic elevator oil include:

- System failure

- Unsafe operation

- Costly repairs

- Legal liability

Target of Hydraulic Elevator Oil

The target of hydraulic elevator oil is to lubricate the hydraulic system's moving parts, reduce friction, and dissipate heat. Without proper lubrication, the hydraulic system can suffer from friction, wear and tear, and overheating, leading to premature system failure.

Summary of Main Points

To keep your elevator's hydraulic system running efficiently and safely, it is crucial to maintain an adequate level of hydraulic elevator oil. Neglecting this critical element can cause significant problems, such as system failure, costly repairs, and legal liabilities.

What is Hydraulic Elevator Oil?

Hydraulic elevator oil is a type of hydraulic fluid used in hydraulic elevator systems. It is designed to lubricate, cool, and protect the hydraulic system's moving parts. The hydraulic system's functioning depends on the oil's viscosity, which affects the oil's ability to flow and transfer energy.

I recently had an experience where my building's hydraulic elevator system failed. The property maintenance crew informed me that the cause of the problem was low hydraulic elevator oil levels, which caused excessive heat build-up leading to system failure. The incident highlighted the importance of the role of hydraulic oil in ensuring the safe operation of the hydraulic elevator system.

The Importance of Regular Maintenance

Regular maintenance and upkeep of your elevator hydraulic system is critical in ensuring its safe and efficient operation. This includes ensuring that proper hydraulic oil levels are maintained. Neglecting regular maintenance can lead to system failure, costly repairs, and legal liability.

I cannot overemphasize the importance of proper maintenance and upkeep of your elevator hydraulic system. It not only ensures the safe operation of the system but also prolongs its lifespan and reduces costly repairs.

Hydraulic Elevator Oil Properties

Hydraulic elevator oil is designed to meet specific requirements, including:

- Viscosity - This property is critical as it affects the oil's ability to flow and transfer energy.

- Anti-wear properties - This ensures the protection of hydraulic system components from wear and tear.

- Anti-foaming properties - This property ensures that the hydraulic fluid's lubricating properties are not affected by air bubbles.

- Anti-oxidants and anti-corrosion properties - This protects the hydraulic system components from oxidation and corrosion.

Hydraulic Elevator Oil Types

There are several types of hydraulic elevator oil available in the market. Selecting the correct oil depends on the hydraulic system's requirements in your building. It is best to consult with a professional elevator maintenance company to select the appropriate hydraulic elevator oil for your building's hydraulic system.

Questions and Answers

Q: What are some signs that indicate the hydraulic elevator oil needs replacement?

A: Some signs that indicate your hydraulic elevator oil needs replacement include excessive hydraulic noise, slow operation, vibration and jerking of the elevator, and overheating of the elevator hydraulic system.

Q: Can hydraulic elevator oil be mixed with other types of hydraulic fluids?

A: No, it is not recommended to mix different types of hydraulic fluids as they can have different properties and can result in ineffective lubrication and cause damage to the hydraulic system.

Q: How often should hydraulic elevator oil be replaced?

A: It is best to follow the manufacturer's recommendation on how often to replace the hydraulic elevator oil. Typically, it is recommended to replace the oil every three to five years, depending on usage and environmental factors.

Q: Can I change the hydraulic elevator oil myself?

A: No, it is not recommended that you change the hydraulic elevator oil yourself. It is best to consult with a professional elevator maintenance company to ensure that the correct oil is selected and safely changed to avoid any potential harm to yourself or the hydraulic system.

Conclusion

Hydraulic elevator oil plays a crucial role in ensuring the safe and efficient operation of your building's elevator hydraulic system. Neglecting regular maintenance and upkeep can have severe consequences, including system failure, costly repairs, and legal liabilities. To ensure the smooth operation and longevity of your elevator's hydraulic system, it is best to consult with a professional elevator maintenance company to select and maintain the correct hydraulic elevator oil.

Gallery

Hydraulic Oil - Grade 32 - 5L - Elevator Equipment

Photo Credit by: bing.com / oil 5l hydraulic grade machine bearing gear hyd room

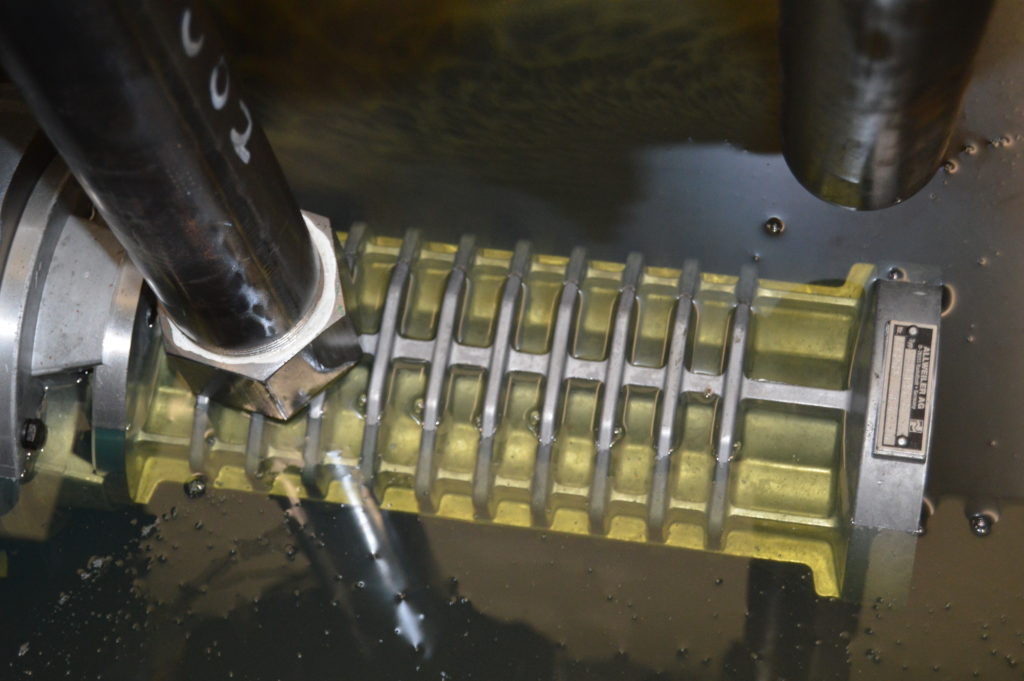

Elevator Hydraulic Oil Cooler | Hydraulic, Spare Parts, Engineering

Photo Credit by: bing.com / spare hydraulic

An Elevator's Hydraulic Oil Is Its Lifeblood. Protect It.

Photo Credit by: bing.com / elevator passing guts

Chicago Elevator Maintenance - Colley Elevator: Cleaning Elevator

Photo Credit by: bing.com / hydraulic elevator fluid cleaning tank chicago il before

Shop Ultra Lube 5-Gallon Elevator Hydraulic Oil At Lowes.com

Photo Credit by: bing.com / lowes elevator hydraulic gallon lube ultra oil