If you're in the construction industry, you know how important it is to have efficient MEP equipment. As industries become more modernized, MEP equipment has become a crucial factor in ensuring that construction projects are completed on time and within budget. In this blog post, we'll dive into the world of MEP equipment, discussing its target, pain points, and benefits. By the end of this post, you'll have a better understanding of why MEP equipment is essential in today's construction industry.

Pain Points in MEP Equipment

One of the main pain points in MEP equipment is the cost of installation and maintenance. The complexity of MEP systems also makes it challenging to maintain and repair, often resulting in costly downtime. Additionally, selecting the right equipment for specific projects can be a tedious process that often requires the assistance of industry professionals.

The Target of MEP Equipment

MEP stands for Mechanical, Electrical, and Plumbing, and the target of MEP equipment is to promote efficiency in these three areas. MEP equipment provides efficient heating, ventilation, air conditioning, lighting, plumbing, and fire protection systems. The technology is used to design, operate and maintain building systems, ensuring clients are receiving the most effective equipment and services.

Summary of MEP Equipment

MEP equipment is an essential component of the construction industry, ensuring high-quality system installations that maintain the efficiency and consistency of building operations. Handling MEP equipment can result in a reduction of expenses and on-time completion of projects, ensuring customer satisfaction. Architects, engineers, and contractors need to work collaboratively in implementing the right MEP equipment, resulting in successful project delivery.

Mechanical Engineering Equipment

Mechanical engineering equipment, primarily used for heating and cooling in commercial buildings, consists of large and complex equipment such as cooling towers, boilers, chillers, and air-handling units. Contractors create a design model that can be auto-generated, giving them flexibility and reducing production times. The equipment is built for high efficiency, including energy savings and low maintenance costs.

Electrical Engineering Equipment

Electrical engineering equipment is one of the essential components of MEP equipment. The electrical design process includes the use of software to create a comprehensive digital model of the building, including the voltage drop calculation and switchboard layout. The equipment installed consists of switchgear, transformers, and various electrical components. Wiring and cabling are also important, requiring precise installation to avoid any potential future accidents.

Plumbing Equipment

MEP equipment related to Plumbing installation can sometimes be tricky, making it necessary to purchase the right types of fixtures and valves. Plumbing installation can lead to issues such as equipment malfunctioning or even flooding. However, plumbing design software and modern MEP-equipped devices are designed to alleviate these concerns.

Fire Protection and Safety

The inclusion of MEP equipment in fire and safety is critical; the system is designed to be flexible and efficient to ensure better firefighter response time in case of emergencies. The system comprises unique devices such as sprinklers and detection devices designed to detect fire in its preliminary stages and reduce the potential for loss of life. The equipment is designed for the ultimate passenger, employee, and company safety.

Question and Answer

What is MEP equipment?

MEP stands for mechanical, electrical, and plumbing, and it refers to the combined equipment used in the construction industry to handle these systems comprising plumbing, HVAC, and electrical systems.

What is the role of MEP equipment?

The primary role of MEP equipment is to provide efficient and effective coordination of several construction activities, including installation, operation, and maintenance.

What factors should be considered when selecting MEP equipment?

When selecting MEP equipment, factors such as maintenance requirements, energy efficiency, and reliability should be considered, as poor equipment can lead to costly downtime.

How does MEP equipment improve the construction industry's efficiency?

MEP equipment ensures proper coordination between mechanical, electrical, and plumbing equipment and improves the construction industry's overall efficiency by ensuring on-time completion of projects and reduced expenses.

Conclusion of MEP Equipment

MEP equipment plays an essential role in the construction industry, ensuring high-quality system installations that maintain the efficiency and consistency of building operations. The proper use of MEP equipment can result in a reduction of expenses and on-time completion of projects, ensuring customer satisfaction. Architects, engineers, and contractors need to work collaboratively in implementing the right MEP equipment, resulting in successful project delivery.

Gallery

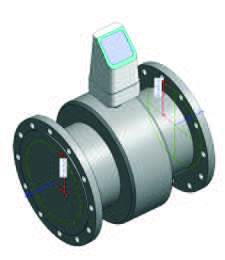

Parametric Revit Mep Families For Manufacturing Of Mep Equipments

Photo Credit by: bing.com / families mep equipment parametric mechanical dimension entire single services set

What Is MEP Engineering? Structural & MEP Design Firm - California

Photo Credit by: bing.com / mep

Parametric Revit Mep Families For Manufacturing Of Mep Equipments

Photo Credit by: bing.com / mep deputed

MEP Coordination | Pepper Construction

Photo Credit by: bing.com / mep coordination construction

BIM Projects: 3D Modeling & Coordination | Hitech BIM Services

Photo Credit by: bing.com / mep revit equipments bim