The National Electrical Code (NEC) 430.102 is an important electrical code that is essential for safety and performance in electrical installations. It covers motor control centers, motor branch circuits, and feeder conductors. Understanding this code is crucial, whether you are an electrician, an engineer, or a homeowner.

Pain points

Have you ever experienced an electrical short circuit or overload in your home or workplace? Have you faced downtime and productivity losses due to motor failures? If yes, then you know how frustrating and costly these issues can be. NEC 430.102 was developed to prevent such situations and ensure optimal safety and performance.

Target of NEC 430.102

NEC 430.102 aims to ensure that motor controller ratings and settings are compatible with the maximum available fault currents and the short time current ratings of the equipment, conductors, and protection devices used. It also specifies the requirements for sizing and protecting motor controllers and feeder conductors, as well as determining the motor branch circuit conductor ampacity.

Main points

NEC 430.102 covers the following topics:

- Motor controller rating and identification

- Motor branch circuits and feeder conductors

- Short-circuit, ground-fault, and overload protection

- Branch circuit and feeder conductor sizing and protection

- Motor control circuit protection

By adhering to these requirements, you can prevent electrical hazards, equipment damage, and productivity losses. Moreover, you can ensure that your electrical installation is up to code and compliant with safety standards.

Understanding NEC 430.102

As an electrician, I have come across many situations where NEC 430.102 has played a crucial role in ensuring safety and performance. For instance, I once had to replace a malfunctioning motor in a production facility. Upon inspection, I found that the installed motor controller was underrated and could not handle the load. By following NEC 430.102 requirements, I installed a new motor controller with the proper rating and protection, along with the appropriate feeder conductors and branch circuit protection. The new installation not only resolved the issue but also improved the motor's efficiency and reduced energy consumption.

Benefits of NEC 430.102

NEC 430.102 offers several benefits, including:

- Ensuring safety and minimizing electrical hazards

- Preventing equipment damage and downtime

- Improving motor efficiency and reducing energy consumption

- Complying with code and regulations

Therefore, it is essential to understand and apply NEC 430.102 requirements in all motor installations and maintenance activities.

NEC 430.102 requirements

NEC 430.102 requires that:

- The motor controller must be rated for the specific motor and load

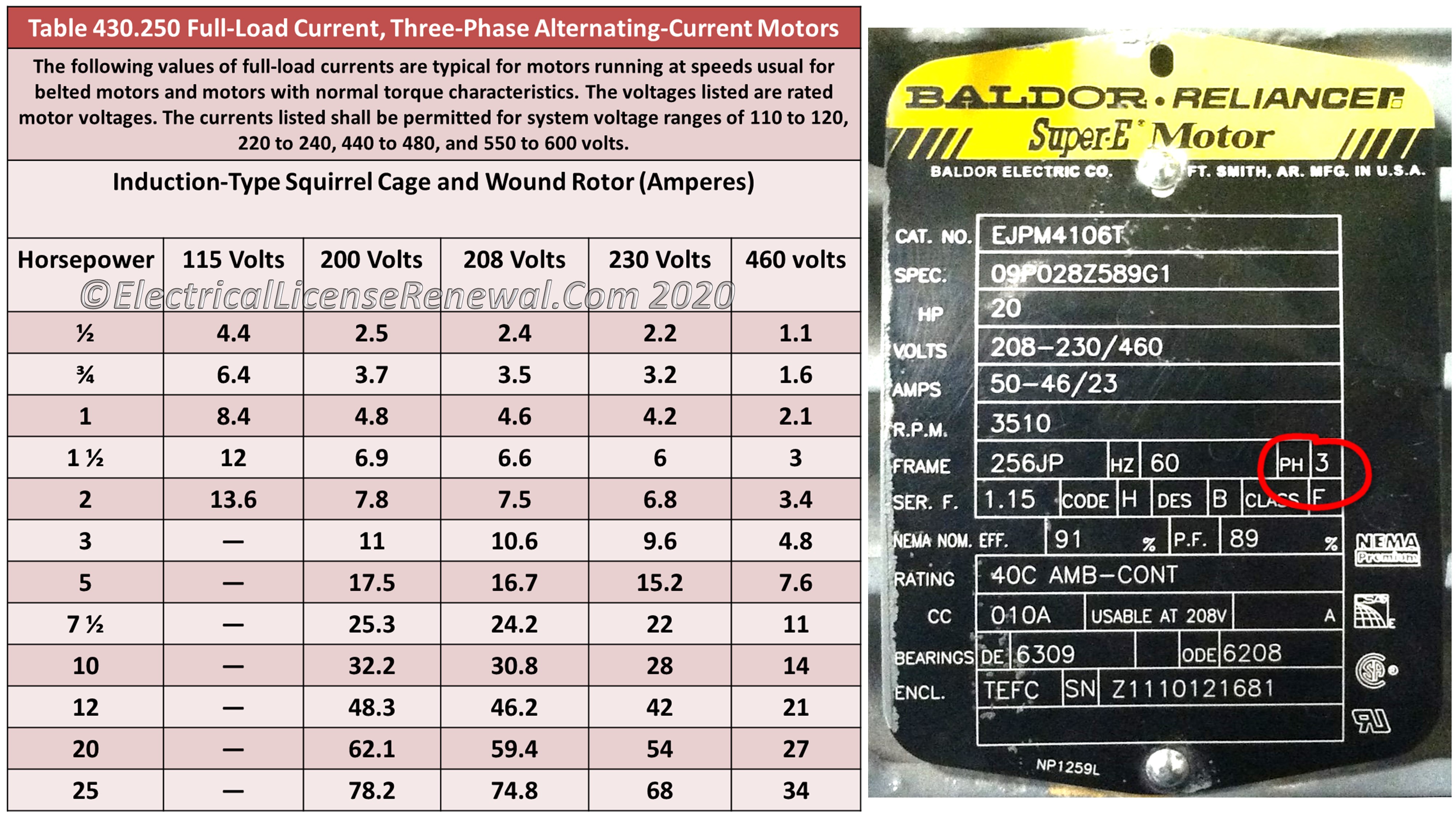

- The motor control circuit protection must be selected based on the motor's full load current

- The branch circuit and feeder conductors must be sized based on the motor's full load current and the conductor ampacity tables in NEC 310.16

- The short-circuit, ground-fault, and overload protection must be sized and coordinated to provide adequate protection

By following these requirements, you can ensure proper selection, installation, and functionality of the motor and its control circuit.

Question and Answer

Here are some common Q&A related to NEC 430.102:

Q1. What is the basic purpose of NEC 430.102?

Ans. The basic purpose of NEC 430.102 is to ensure that motor controllers and feeder conductors are rated and protected against the maximum fault currents and short-time current ratings of the installation.

Q2. What is the difference between motor branch circuit and feeder conductor?

Ans. The motor branch circuit is the set of conductors that extends from the motor controller to the motor. The feeder conductor is the set of conductors that extends from the main service or source to the motor controller.

Q3. What is the importance of motor controller rating in NEC 430.102?

Ans. The motor controller rating ensures that the controller can handle the motor's full load current and inrush current, and it is compatible with the fault current and short-time current ratings of the conductors and protection devices used.

Q4. Do I need to follow NEC 430.102 for all motor installations?

Ans. Yes, NEC 430.102 applies to all motor installations, regardless of the type, size, or location of the motor.

Conclusion of NEC 430.102

NEC 430.102 is a crucial code that ensures safety, reliability, and efficiency in motor installations. By following its requirements, you can prevent electrical hazards, equipment damage, and productivity losses, and comply with safety standards and regulations. As an electrician, I strongly recommend understanding and applying NEC 430.102 in all motor-related activities.

Gallery

NEC 430 DTZ 8LD - TelecomHunter

Photo Credit by: bing.com / nec dtz

6-47 NEC 310.12(A) THRU (D) TO AMPACITY TABLES OF 0 – 2000 VOLTS - 230.

Photo Credit by: bing.com / nec

430.6 Ampacity And Motor Rating Determination.

Photo Credit by: bing.com / nec circuits electrical

NEC Motor Calculations Article 430 | Fuse (Electrical) | Relay

Photo Credit by: bing.com / nec pdf motor electrical code calculations national handbook nfpa buy codebook

NEC CD-430

Photo Credit by: bing.com / nec cd player atabase udio